Phillips announces S Zorb sulfur removal technology for diesel fuel

Although S Zorb SRT for diesel is not yet available for licensing, laboratory test runs show that very low sulfur levels are achievable at significantly lower pressures than conventional hydrotreating processes. The technology is expected to help minimize capital costs and everyday operating expenses while achieving targeted product quality. Pilot plant testing of S Zorb SRT for diesel is currently underway at Phillips research and development facilities.

"S Zorb for diesel is another example of Phillips' dedication to being a leader in clean fuel technologies for refiners," said John Mihm, Phillips' senior vice president of technology and project development. "Phillips has placed the development of this technology on a fast track. Test results indicate that this advanced process will help refiners meet current and future sulfur regulations in Europe and North America. One of the most exciting attributes of the process is its nearly zero net hydrogen consumption."

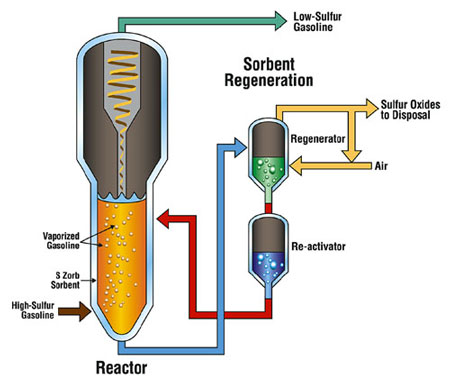

The Phillips technology uses a regenerable sorbent that chemically attracts sulfur and removes it from hydrocarbon streams. Conventional hydrotreating technologies require high-pressure reactors to produce low-sulfur diesel, which results in higher capital requirements and excessive operating costs.

The S Zorb SRT for diesel process, which operates at moderate pressures, shows an ability to reach ultra-low-sulfur levels without significant hydrogen consumption. This low net hydrogen consumption is a critical issue for hydrogen-scarce refineries and those refiners wishing to minimize hydrogen dependency. As an additional advantage, the sorbent material can be regenerated while the unit is operating, allowing for prolonged run times between shutdowns.

Edited by David Nakamura

Managing Editor, Hydrocarbon Online

dnakamura@hydrocarbononline.com