Oxidation Systems

PRODUCTS

-

The XR75 Pharma X-ray is optimized for the quality control of pharmaceutical, nutraceutical, and cosmetic products in thin opaque packaging materials that cannot be inspected manually or with visual systems.

-

Our model combines the depth and experience level of our people with effective tools and processes already in place that are designed to ensure your critical eTMF documents and content are secure, organized, readily accessible, and always in complete compliance with all relevant regulations.

-

Aragen offers choice of CLD platforms, efficient Upstream and Downstream process development

-

Forming part of 3P innovation’s Discover Range, this early-stage development unit uses two sets of die punches to compress pellets and seal them within a blister strip. Used predominantly for dry powder inhalers (DPIs), the ultra-compact filler fits on your lab benchtop.

-

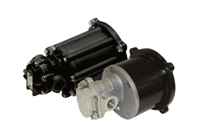

Combining proven design principles with patented features, our Sealless gear pumps are safe, simple, and reliable. Structurally rugged with corrosion resistant materials, Eclipse rotary pumps are an ideal fit for many corrosive liquids. From acids to bases, we cover the entire pH scale.

WHITE PAPERS AND CASE STUDIES

-

Manufacturing Transfers: Delivering 140+ Precision Medical Devices Without Missing A Deadline

Go inside a successful manufacturing transfer of over 140 Class-III silicone medical devices and on-time delivery for a top-30 OEM through expert project management and rigorous validation processes.

-

Disinfection For Purified Water Loop For Kamada Pharmaceuticals, Israel

An Atlantium HOD™ (Hydro-Optic Disinfection) UV system was installed at the outlet of a PW tank to serve as the primary disinfection barrier, with water circulating through the system at 6m³/hr before reaching the points of use.

-

Cooling Tower Crisis: How Hydrogen Peroxide Scrubbed Away The Bacteria Buildup

A West coast power plant needed an immediate solution to clean its cooling tower that was fast, cost effective, and did not require removal and manual cleaning of the tower's fill material.

-

AMERICAN And Partners Install Boltless Restrained Underwater Pipeline System In Ashland, Wisconsin

Beneath the waters of Chequamegon Bay on Lake Superior in Ashland, Wisconsin, about 4,500 feet of 24-inch AMERICAN Flex-Ring Ductile Iron Pipe and a submerged timber crib intake structure were installed to ensure the city’s residents have quality drinking water for the next 100 years. The Ashland Water Intake Project began May 1, 2025, and is now complete.

-

AqueoUS Vets Named A Manufacturing Partner For A Southern CA Water Treatment Facility

In August 2018, Aqueous Vets was selected over existing industry incumbents to supply the Granular Activated Carbon Systems (GACS) for a Southern California Water Treatment Plant.

-

Electronic Body Maps Drive Standardization Across Top-10 Pharma

Learn how a top-10 pharmaceutical client was able to "fundamentally transform the way they execute clinical trials" with the digitization and standardization of pain maps in a diabetic polyneuropathy trial.

-

Re-Engineering A Complex Process For FDA Compliance

Discover the strategies that helped a company navigate a complex and shifting regulatory landscape to rapidly re-engineer a COVID-19 vaccine manufacturing process for FDA compliance.

-

Enhancing Data Capabilities For Greenville Water Utility

The Greenville Water Utility in Indiana is leveraging Qatium to enhance its water management and leak detection capabilities, significantly improving service efficiency.

-

5 Must-Haves For Electronic Batch Records In Life Sciences

Companies still relying on paper-based manufacturing are falling behind. Examine how digital transformation boosts efficiency and reduces errors in this essential shift toward smarter operations.

-

Working Smarter: Empowering Water Operators With Integrated Data

As water utilities face the challenges of sustainability, efficiency, and service quality, digital technology has become a necessity. The right tech can help deliver reliable service, optimize systems, and meet sustainability goals, but integrating the data streams these solutions generate can offer even greater gains – allowing utilities to move faster and achieve more powerful outcomes.

-

Online Total Nitrogen Analysis Of Reverse Osmosis Reject Water Reduces Permit Compliance Expense By $350,000 Annually At Beverage Bottling Plant

Learn how a beverage plant cut its annual Reverse Osmosis reject water hauling volume by 50%. Real-time Total Nitrogen monitoring reduced compliance costs by $350,000 and eliminated discharge penalty risk.

-

Vaccine Fill Line Operations

Learn how adopting a harmonized, risk-based validation strategy across global sites can reduce operational readiness timelines and drive improvements in equipment effectiveness and regulatory compliance

NEWS

-

Agilitas Energy Expands Into Hydropower With Acquisition Of Two Projects In West Virginia And Maryland6/24/2025

Agilitas Energy, a leading developer and operator of renewable energy and energy storage systems, today announced the acquisition of two late-stage hydropower development projects from Advanced Hydro Solutions.

-

Shell Expands Gulf Of America Leadership Position With Dover Development4/8/2025

Shell Offshore Inc. (Shell), a subsidiary of Shell plc, today announced the start of production at Dover, the second subsea tieback connecting new wells to the existing infrastructure of the Shell-operated Appomattox production hub in the Gulf of America.

-

Enhanc3D Genomics Launches Suite Of 3D Multi-Omics Solutions To Accelerate Drug Development1/14/2025

Enhanc3D Genomics (‘Enhanced’ or ‘the Company’), an innovator in 3D genomics technology, today announced the launch of a suite of integrated multi-omics solutions to accelerate and improve the precision of drug discovery.

-

Consulta Remedios Selects Kevel's Retail Media Cloud To Power Its Next-Generation Advertising Platform5/2/2025

Kevel, the leading provider of API-based retail media ad serving technology, today announced that Consulta Remédios, Brazil's largest medicine price comparison platform, has selected Kevel's Retail Media Cloud to power the development and enhancement of its in-house retail media network.

-

NX Filtration And Eau d'Azur Partner For Advanced Micropollutant Treatment In Nice8/25/2025

NX Filtration, a global leader in advanced hollow fiber membrane technology, is proud to announce its collaboration with Eau d’Azur, the public company responsible for drinking water and wastewater services for the Nice Côte d'Azur Metropole.

ABOUT

Oxidation Systems

Waste treatment, ground water remediation and food processing are some of the areas that heavily rely on oxidation systems. Ozone generators, hydrogen peroxide and potassium permanganate are some of the oxidation systems that are important in different oxidation processes. The acquisition of these oxidation systems can be easily done through specialized dealers. It is advantageous to deal through these dealers since they have vast knowledge of what are essential for different processes. Some of these dealers design sell and in certain instances lease these systems. Their experience with advanced oxidation systems, ozone and potassium permanganate makes them the best people to use when such and related concerns arise.

There is no doubt about the transformation that the chemical oxidation technologies have taken. Specialists in the oxidation field work hand in hand with the interested parties in solving all their oxidation related needs. This sequential process begins with the selection of the appropriate oxidation need. Once a technology is selected, they work with the client step by step in designing the system that is suited to one’s application. Other than the identification and assembly, they will provide assembly and maintenance services.

There are certain elements of oxidation systems that one should always know when dealing with these systems. Injection trailers, metering systems and pilot testing systems are some of the things that might be relevant for different oxidation system types and scales. For instance, one involved in ozone oxidation need to be familiar with ozone generators and ozone pilot testing systems.

Like any other process, oxidation need ought to be measured by considering the aspects of benefits and cost. This calls for meticulous review of the energy and chemical costs as well as the by-products. Many tend to forget about the by-products during the initial planning phase until when they have to disinfect them.