Catalysts

PRODUCTS

-

At ProPharma, we offer a unique approach to the traditional Clinical Research Organization (CRO) Full-Service Provider (FSP) model.

-

The QPM0106 is a packaged, high-power amplifier fabricated on Qorvo's production 0.25 um GaN on SiC process that operates from 1.0 - 6.0 GHz and provides 45.4 dBm (35 W) of saturated output power.

-

Every capsule and tablet begins with an idea. It takes a professional and innovative manufacturing partner to turn that idea into a reality. Enter Natoli, a name synonymous with excellence in pharmaceutical equipment and services. From the early stages of formulation to the grand scale of full-blown production, Natoli offers a seamless journey through every step of the process. Whether you’re unsure of how to start or how to finish, Natoli can guide the way.

-

The UJ4C075044L8S is a G4 SiC FET based on a unique ‘cascode’ circuit configuration, in which a normally-on SiC JFET is co-packaged with a Si MOSFET to produce a normally-off SiC FET device.

-

PHCbi brand’s 19.5 cu.ft. (554 L) pharmaceutical refrigerator with adjustable shelving and forced-air circulation help helps ensures uniform temperature control from 2°C to 14°C. The sliding glass door design minimizes air loss and supports easy access in high-use environments. A microprocessor controller and OLED display feature excellent visibility and intuitive operation utilizing control buttons that provide convenient, yet secure, user commands. Refrigeration temperature can be displayed in 0.1°C increments, and the minimum and maximum temperatures within the previous 12 and 24 hours are displayed. Audible and visual alarms with adjustable setpoints warn of deviations from setpoint temperatures, and all alarm conditions are displayed and recorded. A password-protected control interface assures operational security. Natural hydrocarbon refrigerants and inverter compressor technology deliver quiet, energy-efficient performance with fast recovery. ENERGY STAR® Certified.

WHITE PAPERS AND CASE STUDIES

-

Leveraging Single-Use Solutions To Solve Working Cell Bank Challenges

Discover how custom manifolds enhance allogeneic therapy development from formulation to commercialization by improving process control, scalability, and efficiency.

-

Streamlined Facility Design: A Success Story

Examine how one medium-sized US company's need for a new aseptic compounding and fill-finish facility was addressed with a tailored solution within a challenging time-frame.

-

Online Total Nitrogen Analysis Of Reverse Osmosis Reject Water Reduces Permit Compliance Expense By $350,000 Annually At Beverage Bottling Plant

Learn how a beverage plant cut its annual Reverse Osmosis reject water hauling volume by 50%. Real-time Total Nitrogen monitoring reduced compliance costs by $350,000 and eliminated discharge penalty risk.

-

Accelerating A Complex Molecule From CLD To cGMP In 12 Months

Learn how to mitigate technical risk, implement parallel process development, and design custom purification strategies for highly sensitive novel modalities to accelerate to cGMP material.

-

Preserving Pressure, Protecting Service: Upgrading Hydrant Infrastructure In Kent County

When Kent County Water Authority faced the urgent replacement of a 94-year-old hydrant tied to a 1931 cast iron main, they were determined to maintain fire protection and avoid customer disruption.

-

Digital Outcome Measures Approved As Primary Endpoint In Cardiopulmonary Study

Discover how a clinical development program was saved using objective, continuous digital outcome measures.

-

Revolutionizing Wastewater Management In Four Cities Through Water Mixing

Historically, lift station operators have turned to chemical treatments as the primary means of managing grease buildup. However, these methods carry inherent drawbacks.

-

ArxZyme™ Acetone Removal For AMPAC Fine Chemicals

AMPAC faced a critical challenge with acetone management. The high acetone levels in the effluent from its chemical processing operations required an effective industrial wastewater treatment solution to meet environmental regulations and ensure safe discharge.

-

RO Protection At Formosa Plastic Group, Taiwan

In this case study, learn why Formosa Plastics Group in Taiwan used Atlantium Technologies' HOD UV system to protect RO membranes from biofouling, resulting in cost savings and plans for further installations.

-

Robust, Scalable Strategy For Monodisperse Nanosuspensions Of Poorly Soluble Drugs

By tailoring the formulation strategy, selecting the appropriate excipients, and fine-tuning process conditions, see how our team was able to improve bioavailability and in vivo exposure.

-

MilliporeSigma's 97-Day Implementation Success Story

Read how MilliporeSigma transformed validation processes with a digital validation system to achieve compliance in just 97 days, as well as learn key takeaways from their swift transition.

-

Vassar WWTP Eliminates Rags To Protect Equipment, Biosolids Quality

The Vassar wastewater treatment plant (WWTP) in Michigan, confronted persistent challenges from non-dissolvable solids by adopted Duperon's Dual Auger System (DAS) to address these issues effectively.

NEWS

-

Silo Pharma Expands Intellectual Property Portfolio With Patent Application For Exclusively Licensed Alzheimer's Drug4/28/2025

Silo Pharma, Inc. (Nasdaq: SILO) (“Silo” or the “Company”), a developmental stage biopharmaceutical company focused on novel therapeutics and drug delivery systems, today announced the filing of a patent application with the U.S. Patent and Trademark Office (USPTO) focused on the neurology drug SPC-14, an intranasal compound for the treatment of Alzheimer’s disease (AD) exclusively licensed to Silo Pharma from Columbia University.

-

Baden-Württemberg's Largest Solar Park Now In Operation5/28/2025

EnBW has commissioned its solar park in Langenenslingen-Wilflingen (district of Biberach in the southwest of Germany).

-

Agilitas Energy Expands Into Hydropower With Acquisition Of Two Projects In West Virginia And Maryland6/24/2025

Agilitas Energy, a leading developer and operator of renewable energy and energy storage systems, today announced the acquisition of two late-stage hydropower development projects from Advanced Hydro Solutions.

-

Anritsu Supports Evaluation Of 5G NR NTN Devices For Satellite-Based Communications7/29/2025

Anritsu Corporation, a global leader in test and measurement solutions, is pleased to announce that its Radio Communication Test Station MT8000A, a measurement solution for 5G devices such as smartphones, now supports evaluation of 5G NR NTN devices for non-terrestrial networks (NTN), which enables communication via satellite.

-

Masdar And Iberdrola Announce €5.2B UK Offshore Wind Deal And Full Energization Of 476MW German Offshore Wind Farm7/10/2025

Masdar, a global clean energy leader, and Iberdrola, one of the world’s largest energy companies, have reached two major milestones with a €5.2B co-investment in the UK’s East Anglia THREE offshore wind farm – the largest offshore wind transaction of the decade – and the full energization of their 476MW Baltic Eagle project in Germany.

ABOUT

Catalysts

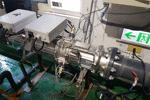

Catalysts work by changing the structure of a molecule or by bonding to reactant molecules causing them to combine, react, and release a product or energy. For example, a catalyst is required in order for oxygen and hydrogen to bond, combine and produce water.

Catalysts increase the rate of chemical reactions. Unlike a reagent that gets consumed as apart of the chemical reaction, catalysts do not get consumed in the reaction. They can actually participate in multiple chemical transformations.Catalysts can be organic, synthetic or metal.

All processes need energy to take place. Processes require a very high level of energy in order to spark or start if a catalyst isn’t present. When a catalyst is present the amount of energy required to spark the reaction is lowered and that makes the reaction happen faster and more efficiently.

Catalytic effects vary depending on other substances present that are a part of the chemical reactions. There are certain substances that can inhibit the effectiveness of a catalyst like poisons, and other substances that promote or increase the effect of the catalyst. Inhibitors or negative catalysts are very important in medicine to treat mental illnesses, high blood pressure, cancer and many other diseases.

Catalysts are often used to help crack, or split, larger organic molecules like hydrocarbons into simpler molecules. It does this by breaking carbon-carbon bonds. The speed of the splitting process depends heavily on what specific catalyst is used and the temperature. Applications of this technology include oil and petrochemical industries.